The cold snap that struck the UK during January this year puts metal gates through their paces to a degree of which few homeowners are aware. With temperatures well down at minus 4 degrees and accompanying snow, ice, and 'freeze and thaw cycles,' weaknesses manifesting under milder conditions escape detection. But as things stand to clear, it’s a good time assess the condition of the metal gates.

One of the key principles to keep in mind though is that metal itself expands or contracts depending on the changes in temperatures. The last cold spell brought temperatures fluctuating between -4°C to 9°C during the day and night. This is a cycle that puts strain on all joints, fixes, and welds in the gate system.

Systematic Inspection Methodology

Don’t just scan your gates and assume that everything is in good shape simply because they’re operating correctly and opening/closing correctly etc. The damage that cold weather can cause can often lie hidden in areas that are not immediately apparent. You’ll want to work through this checklist in an orderly fashion.

The condition of the surface coating

The beginning would be the paint or powder coat condition. Cold weather factors affect paint or powder coat differently.

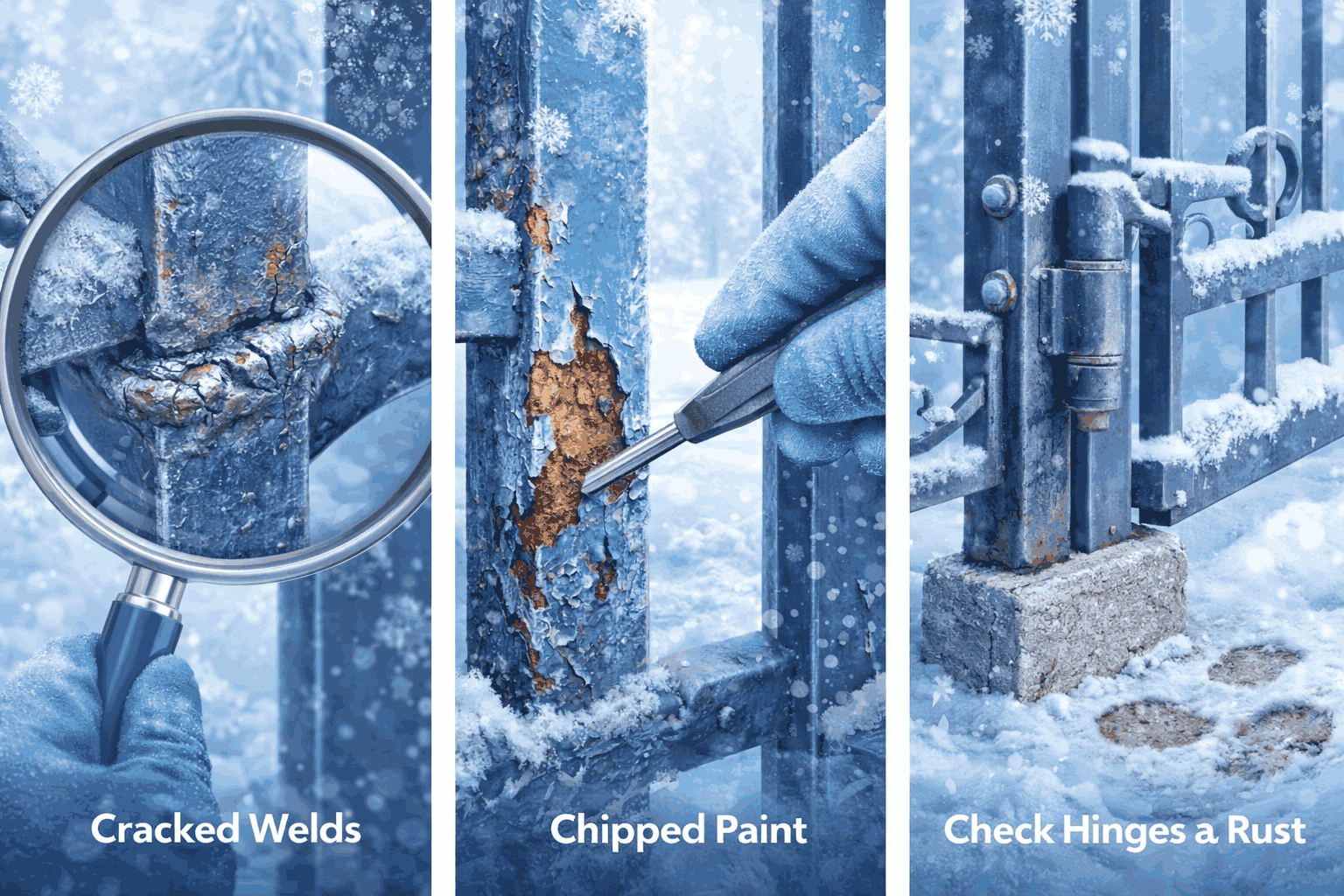

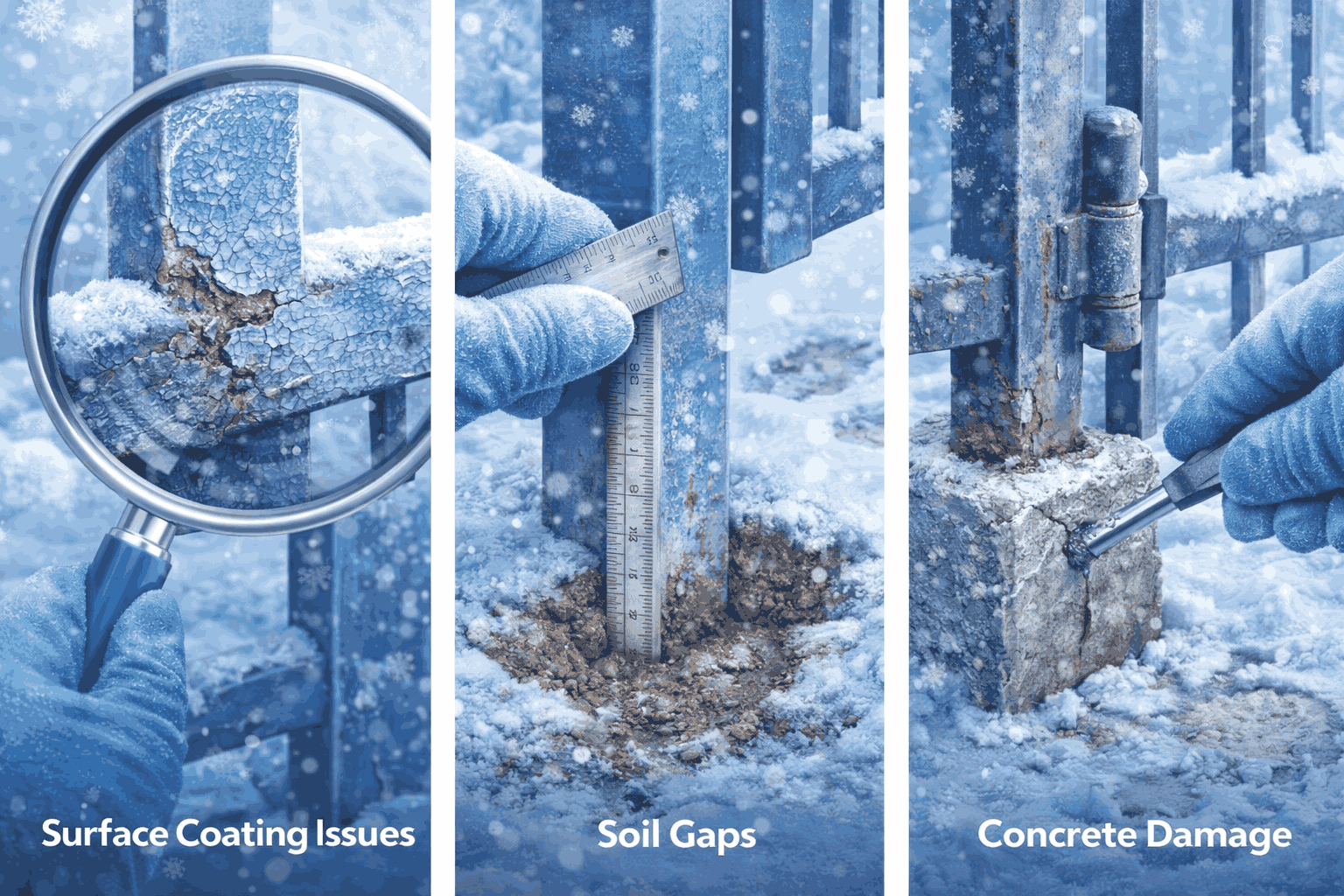

Examine for very fine cracks within the powder coating. These are evidenced by hairline fractures that often originate from fixings and welds. This occurred because the coating shrunk at a different rate to the substrate beneath and developed stress fractures as a result. They are very fine but lead to water intrusion beneath the coating to start the corrosion process.

Observe regions where there was significant accumulation of ice and snow. The continuous action of wet, freeze, and thaw is a vigorous attacker of the coating. Check if the coating has become dull, chalky, or has some texture compared to other regions that were not damaged.

One should focus on horizontal areas where water could collect. Top rails, scroll work, and frame ledges exhibit more freeze/thaw damage to the coating.

Weld Integrity

Welds are the strongest locations on well-made gates, but they are also stress concentrators. Cold weather exposes existing weaknesses in the welds and can also introduce new issues.

Examine every weld visually. Look for cracks, no matter how small, running along or across the weld beads. These could be barely perceptible yet represent severe weaknesses in the structure. A magnifying glass may be necessary. The cracks that showed up during the cold weather spell will rapidly propagate when the gates resume normal usage.

Look for rust staining around welds. This is an indication of moisture penetration during the freeze. Although welds may appear fine, the rust on the surface is an indication of a failure of the protective coat on critical areas of the structure.

To test a weld, apply pressure on the two items that are weld-connected. If a weld is sound, there should be no movement. If there is any movement or shifting, it is a sign that a weld is failing. Do not push too hard. Only apply firm pressure.

Condition and Operation

Hinge pins should be checked for rust on the surface that wasn’t there prior to the cold snap. Water invaded the hinge assembly, freezing it. The resulting expansion forced parts apart at a microscopic level, breaking surface films of lubricants.

Investigate the area where the hinges are attaching to the posts and the gate. Look out for paint/powder coating cracks at the point of attachments. Check if there are rust stains present, indicative of water entering the area. Check if the hinges are loose by attempting to move them when the gate is shut.

Note resistance to stiffness when running. Hinges that are noticeably stiffer than before the freeze have internal damage or lubrication damaged by the formation of ice.

Examine the area around the post and soil/concrete. Gaps which were not there before represent where the freezing action heaved the posts up, followed by a settlement. Gaps introduced water into the foundations.

Inspect haunching of concrete. New cracks show that freeze-thaw action damaged the concrete. Knock on concrete with a solid object – solid concrete makes a clear ring. It will be dull if the concrete is damaged, and may be slightly soft.

In the case of in-ground posts, try probing around the foundation, if possible. A loose soil area or space between the post and soil suggests that the soil was disturbed by frost action.

Moving Forward

Metal gates that have withstood this cold weather without sustaining much damage should serve you well for a long time. The ones that show signs of malfunctioning should be looked at before another cold weather condition exposes their weaknesses. The January 2026 freeze has thoroughly tested the gates. Let’s consider this experience a forced stress test, where we get a clear indication of what’s good and what’s not. The gates that have come out of this test with flying colours demonstrate the quality of the gates and their installation. On the contrary, gates with issues show where the investment is required.

And don’t forget, if you’re looking for new gates for your property, be sure to check out our range of gates.